IMS Crews Work Hard To Brace Facility for Old Man Winter

DEC 03, 2024

Indianapolis Motor Speedway shines with pristine aesthetics when the gates officially open in May each year. From the smell of fresh spring air to seeing lush, green grass and fresh paint on structures, IMS must be ready to greet hundreds of thousands of fans each year.

But the expansive, 963.4-acre property doesn’t come alive each spring without proper maintenance months prior.

It may be the offseason for racing, but it’s project season for the IMS Facilities team.

“There are noticeable changes now until March,” said Tyrone Garrison, vice president of facilities at IMS. “Input happening right now affects the outcome next year.”

IMS also features an 18-hole golf course designed by famous golf course architect Pete Dye. Four holes of Brickyard Crossing Golf Course are in the Speedway's infield, with the other 14 holes adjacent to the back straightaway.

Between the golf course and several turf parking lots inside and outside of the track, ensuring all areas remain in good condition requires plenty of attention.

“Everything gets sprayed,” said IMS Grounds Superintendent Jason Stewart.

There are over 600 acres of turf between the golf course, parking lots and green areas between roadways. All require being sprayed with weed killer and poison ivy prevention in addition to 30 of the grassy acres being overseeded.

To keep that much turf in good condition throughout the summer months requires more than 5,000 sprinkler heads. Those must have the water removed this time of year to eliminate freezing since Indianapolis is in a colder climate, and the Central Indiana racetrack isn’t immune from the feeling the effects of Old Man Winter.

“It never really stops, especially from a facilities standpoint,” Garrison said. “We don’t have a break.”

Nearly 75 percent of the infrastructure at IMS is exposed to the elements. Over 3,000 fixtures need to be winterized to withstand the cold temperatures, snow and ice.

Maintenance crews shut down and drain every urinal, trough, toilet and faucet. Gas and electricity are turned off.

Work doesn’t halt around IMS once freezing temperatures do arrive.

“How deep of a freeze we get into allows us to do other things,” Stewart said. “If we get a deep freeze, we’re able to take heavier equipment out to the golf course, and we’ll be more effective at removing trees and pruning. Everything has to be delicate if the ground stays thawed.”

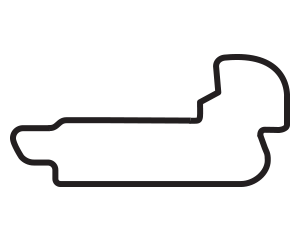

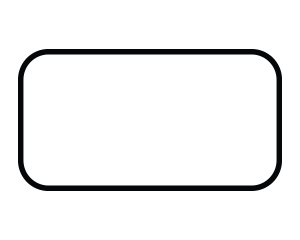

The racing surfaces of the 2.5-mile oval and 2.439-mile, 14-turn road course require a watchful eye during the winter months, too. After all, that’s arguably the most important aspect of the facility. Without a racing surface, there’s no racing. Without racing, the gates aren’t open.

The asphalt racing surfaces react the same as normal roadways in winter months with conditions allowing the threat of cracks and potholes.

Where IMS differs from roadways is many of the 3.2 million original bricks are still below the asphalt, which creates additional challenges.

“We still have the original bricks under there, so this thing acts a lot different than a traditional road,” Garrison said. “It moves, and it has areas that we know will move up to several inches.”

The maintenance crew elects to repair problem areas by hand rather than using large equipment.

“We literally have people out there crawling around on their hands and knees with ketchup squirt bottles filling cracks,” Garrison said.

That attention to detail is why IMS is always ready to host over 300,000 race fans on the last Sunday in May. While the first Indianapolis 500 was held in 1911, the grounds opened in 1909. Maintaing a cathedral approaching 116 years old is an undertaking that Stewart, Garrison and their team of 30 members, 15 full-time and 15 seasonal, don’t take for granted.

“Every year, we want to make this place better,” Garrison said. “Every time somebody shows up here, whether you notice it or not, we want the feeling that the place is getting better and it’s evolving.”