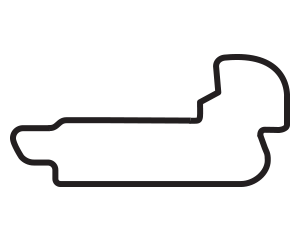

New, Eco-Friendly Firestone Guayule Tire Racing at Nashville

AUG 03, 2022

The Firestone Firehawk guayule race tire will make its on-track debut this weekend at the Big Machine Music City Grand Prix on the streets of Nashville, another milestone in the efforts of Firestone and the NTT INDYCAR SERIES to promote sustainability.

This new, eco-friendly tire debuted in May during the Ruoff Mortgage Pit Stop Challenge on Race Week of the 106th Indianapolis 500 presented by Gainbridge. It is partially composed of a new sustainable natural rubber derived from the guayule shrub, which requires less reharvesting than traditional sources of rubber.

“The introduction of guayule natural rubber to America’s pre-eminent open-wheel racing series speaks to the confidence we have in the technology and its promise as a scalable, sustainable and domestic source of natural rubber—a vital raw material,” said Nizar Trigui, chief technology officer and group president, Solutions Businesses, Bridgestone Americas, Inc. “This milestone represents our commitment to realizing a more sustainable future for tires, racing and mobility.”

All NTT INDYCAR SERIES teams will use the guayule (WHY-U-LEE) tire as the alternate tire this weekend at Nashville.

The guayule natural rubber is located within the Firestone Firehawk’s sidewall. Bridgestone race tire engineers decided to use the guayule rubber in the entire sidewall because that area is made up of the most natural rubber. This allows Firestone to maintain the same quality and performance as the existing race tire.

Bridgestone plans to incorporate guayule natural rubber into more of its race tires starting in 2023. That effort will begin with using guayule rubber at multiple Firestone tire tests throughout the year to see how its use can be expanded for the 2023 race season.

Guayule is a drought-resistant, heat-tolerant woody desert shrub native to northern Mexico and the southwestern United States. Natural rubber can be extracted from the branches, bark and roots of the shrub.

The racing debut of the guayule tire is an important step in a journey that started 10 years ago for Bridgestone. In 2012, the company launched a guayule research initiative aimed at diversifying the world’s natural rubber supply.

Guayule is not currently a commercial crop, so Bridgestone must produce the seed and grow the crop. The shrub doesn’t compete with traditional food source crops, instead using a grower’s existing row crop equipment to save costs.

After years of development and research, Bridgestone has landed on the variations and growing conditions that it expects will make guayule a commercially viable crop and is actively building an ecosystem to bring guayule-based rubber to market.

To date, Bridgestone has invested over $100 million in its efforts to commercialize guayule, achieving major milestones such as producing the first tire made from guayule-derived rubber in 2015 and continued expansion of its molecular breeding program to improve important traits, such as rubber content and rubber yield.

Bridgestone aims to commercialize use of guayule rubber in tires by 2030 and will continue to improve guayule productivity through sustainable methods.

Guayule gives Bridgestone the opportunity to reduce the risk of relying on a single source of natural rubber and has impactful sustainability benefits. Further, it gives Bridgestone the opportunity to localize production of a key material in the United States.

The adoption of guayule tires continues Firestone’s century-plus tradition of using the extreme conditions of open-wheel racing as a proving ground to advance its tire technology. Through racing, Firestone tested many industry-shaping innovations like non-skid treads, low-pressure balloon tires, gum-dipping to insulate tire cords against internal heat, and nylon cords.