HPD simulator a tool for total car performance

SEP 19, 2013

The throttle trace corresponds to Scott Dixon’s audio transmission of a surprising wind gust in Turn 1 of the Indianapolis Motor Speedway oval. Fortunately for the 2008 Indianapolis 500 winner, there aren’t consequences but a jolt to the car and its occupant.

The curveball is a variable programed into Honda Performance Development’s Driver-in-the-Loop (DIL) simulator at its tech center in Brownsburg, Ind., which opened in May. Similar technology has been utilized by HPD’s sports car program since 2007 in England.

The HPD DIL simulator offers teams the opportunity to replicate on-track situations – such as changing track and ambient temperatures, tire grip and wind speed/direction -- and test chassis setups, aerodynamics, engine mapping and development paths in a cost-effective environment.

Additionally, customized simulations can be utilized for drivers to learn racetracks and/or for driver development.

“The development is long road and a constantly-changing road. Tire models change, aerodynamics, it’s a constant evolution,” said Dixon, driver of the Honda-powered No. 9 Target Chip Ganassi Racing car. “The biggest step for me last year was every three or four races I would have to fly to England, so at least now in Indy it’s a lot more accessible to many people.

“The development is long road and a constantly-changing road. Tire models change, aerodynamics, it’s a constant evolution,” said Dixon, driver of the Honda-powered No. 9 Target Chip Ganassi Racing car. “The biggest step for me last year was every three or four races I would have to fly to England, so at least now in Indy it’s a lot more accessible to many people.

“You can simulate days at Indy and say it’s 95 degrees and there’s a big tailwind in 1 or trying to work out scenarios where you have not so good things going on. You can go to a broader sort of range with aero kits. It’s exciting.

“For people who haven’t been on a circuit, it’s good for the braking spots and the turns. There are plenty of applications. You can run at circuits to potentially test a new driver and get references.

“It’s much easier to crash in this than on the track. The consequences are a lot less when you do a simulation.”

The new-for-2015 Acura NSX is being designed, developed and built in central Ohio, and HPD vice president and COO Steve Eriksen said the Indiana tech center is an important development tool “that will bring benefits to all of our motorsports activities, through a focus on total vehicle performance encompassing both engine and chassis.”

“If you can build a simulation model of the car, of the engine and of the tires, and you have a simulation model of the circuit, this tool can be used to help you,” he said. “We’ve been utilizing simulators on our racing programs since 2007 and typically those were for our sports car programs. In those cases, the drivers we were using for development activities were UK-based, so that made perfect sense to have our simulator in the UK. Now that we’re back in engine competition in INDYCAR, it made perfect sense to bring a simulator to the heart of IndyCar racing.

“That simulator can serve not only serve our INDYCAR customers but our sports car customers in America and other formulas that utilize Honda technology. It’s very much matched to Honda’s approach of trying to do R&D where your customers are, and that is mirrored by this activity.”

Because it’s a virtual world, Eriksen noted, you can test something that exists or create something that doesn’t exist and use it as a target setting.

“Such as on an engine, what do you want the torque curve shape like?” he said. “You could put on a different torque curve shape that doesn’t actually fit the current engine and that made a huge difference in lap time. How can you develop an engine to match that torque curve? “Same thing for the car’s aerodynamics. You can say I want these characteristics for aero balance, how does the car handle and you get the driver feedback well before you’ve made any parts. It will be invaluable going forward.”

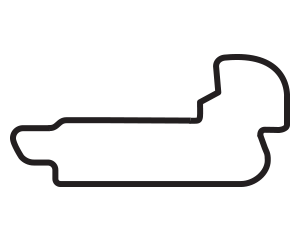

The driver is immersed in the simulation – from wearing a full race suit to seeing a laser-scanned, 180-degree image of the circuit on the console to feeling the undulations of a road course such as Sonoma Raceway. HPD engineers implement and monitor programs requested by teams or drivers, with real-time data. It’s realistic, said a perspiring Dixon after exiting the seat.

“You have to be able to feel it in the car,” Eriksen said. “It’s a matter of trying to tune in every single element. It can help you narrow down what you plan to test at the track. There is no simulation that can’t be uniquely correlated by reality on the track. This is not a replacement for track testing; it’s a method to take your track testing and make sure you’ve tested the very best things.“You have the ability to measure forces in a simulator that are impractical and impossible to measure on a real car.”